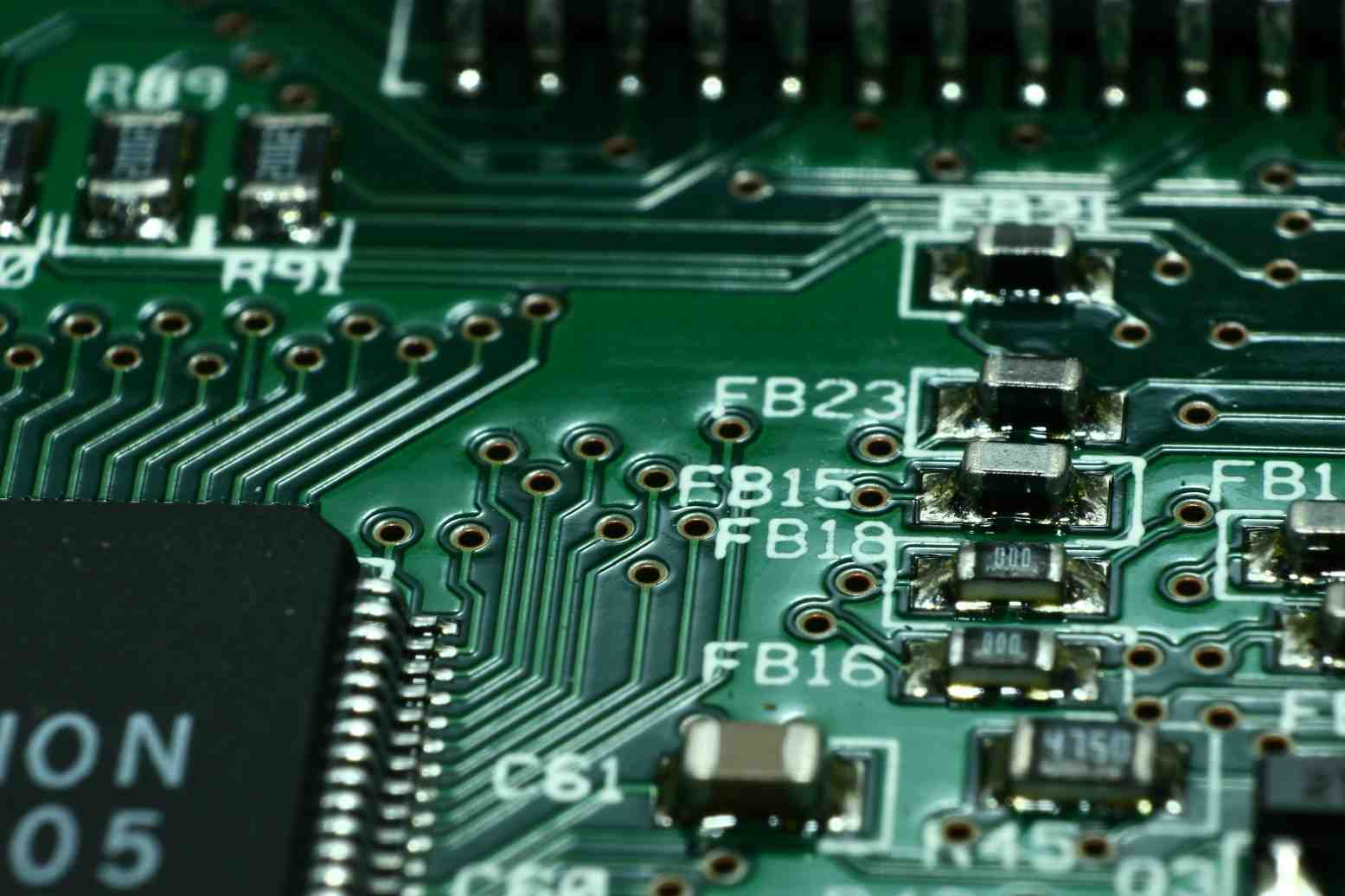

In the ever-evolving world of electronics, Printed Circuit Board (PCB) assembly plays a pivotal role in enabling the devices and technologies we rely on daily. There will be a dramatic shift in PCB assembly shortly due to the extraordinary rate of technological advancement.

This article will examine how PCB assembly is being transformed by new trends and technologies that make it more efficient, compact, and sustainable.

Miniaturization and Component Integration

One of the most significant trends in PCB assembly is the drive towards miniaturization and component integration. As consumers demand smaller and more portable electronic devices, manufacturers are under pressure to create compact and powerful PCBs. Modern technologies like System in Package (SiP) and Multi-Chip Modules (MCMs) allow for the miniaturization and simplicity of printed circuit boards.

Miniaturization enhances the aesthetics of electronic devices and contributes to improved energy efficiency and performance. As a result, we can expect to see even smaller and more powerful electronic gadgets in the future.

1. Flexible and Wearable Electronics

The future of PCB assembly also includes a significant focus on flexible and wearable electronics. Traditional rigid PCBs give way to flexible (FPCBs) and printed electronics, which can be bent, twisted, and integrated into clothing and accessories. These innovations have paved the way for intelligent clothing, fitness trackers, and even medical devices that can be worn comfortably.

Flexible PCBs open up endless possibilities for designers and engineers, making electronics more adaptable to our daily lives. Whether it’s a smartwatch with a curved display or a medical sensor embedded in clothing, the flexibility of PCBs is revolutionizing how we interact with technology.

Also Read: AI Sentinel: How Artificial Intelligence is Transforming Cybersecurity

2. Sustainable Manufacturing

As the world becomes increasingly environmentally conscious, ELE PCB Assembly is moving towards more sustainable manufacturing processes. Companies are making strides towards a more sustainable manufacturing process by using renewable resources, cutting waste, and optimizing energy usage.

Additionally, recycling and reusing electronic components are becoming more commonplace, reducing the electronic waste generated by outdated devices.

Sustainable PCB assembly benefits the environment and aligns with consumers’ values, making it a significant selling point for electronics companies.

3. Advanced Materials and 3D Printing

Advanced materials and 3D Printing are pivotal in the future of PCB assembly. Conductive inks, graphene, and other novel materials create PCBs with enhanced conductivity and thermal properties. Additionally, complicated printed circuit boards (PCBs) with complex patterns that could not be manufactured using conventional methods are now being made possible with 3D Printing.

These materials and manufacturing techniques advancements lead to more efficient and reliable PCBs, crucial for developing cutting-edge technologies like 5G networks and autonomous vehicles.

Also Read: All You Need To Know About Virtual Reality

Conclusion

The future of PCB assembly is marked by exciting innovations that promise to make electronics smaller, more flexible, and more sustainable than ever before. From miniaturization and component integration to flexible and wearable electronics, these trends are reshaping the electronics industry and opening up new possibilities for technology enthusiasts and manufacturers alike.

As we embrace these developments, businesses must keep up with the latest trends to be competitive and satisfy customers’ ever-changing wants. The revolution in PCB assembly is not just a technological shift; it’s a transformation that will shape how we live and interact with electronics in the future.